MTX-IoT-S – new modem with 8x digital I/O and 2x ADC

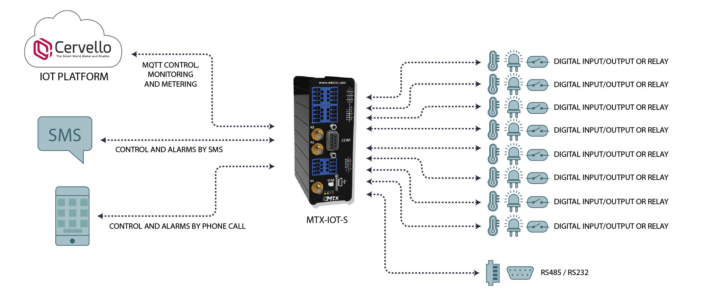

Maritex and MTX present the new MTX-IoT-S, a 4G (LTE), 3G and 2G modem programmable and characterized by its 8 digital inputs/outputs and 2 ADCs that convert analogical signal to digital (at 4-20mA).

In addition, it includes other interfaces such as RS232 and RS485, relay, USB 2.0, possibility of working in Ultra Low Power mode, backup battery, etc. All this, together with the option of adding GPS or RF communications through its expansion port, make it a benchmark in its segment, both in terms of capacity and power, as well as the number and variety of interfaces.

With the new MTX-IoT-S , you’ll be able to control and monitor remote devices. This new modem can send alarms by SMS or voice call if there’s any change in the devices connected to any of its 8 digital inputs. It also has the ability to send telemetry with real-time measurements from up to 8 digital inputs via MQTT to, for example, Cervello IoT Platform . MTX-IoT-S also allows to remotely manage via MQTT, Telnet, SMS or voice call up to 8 relays or digital outputs. Another capability of this modem is to automatically activate or deactivate up to 8 relays or digital outputs depending on the modbus registers collected. In addition, you can automatically notify this status change to the Cervello IoT Platform using MQTT.

MTX-IoT-S include MTX-Tunnel, which makes it a powerful gateway without the need of further programming skills. It is also compatible with Cervello IoT Platform, allowing you to manage all your devices and keep an inventory in an easy and secure way.

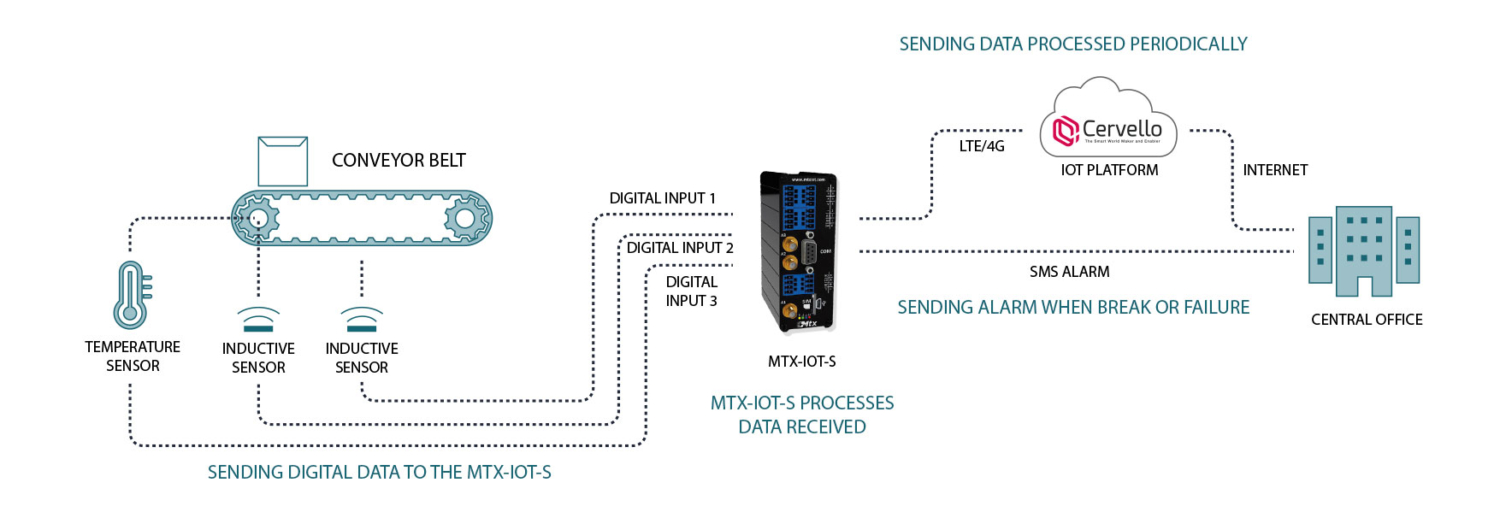

Case Study: Conveyor Belt Monitoring

In a smart environment of management, control and industrial automation, one of the key elements to anticipate failures and increase productivity is to be able to monitor the status and use of conveyor belts of any kind of sector, whether it is for logistics or manufacturing. Thanks to the data obtained, the behavior of the belts can be studied (dilatation, deterioration, irregular advance) thus creating patterns that allow to detect failures in the process. This way, it is possible to optimize the maintenance of the conveyor belts, increasing productivity and reducing the problems arising from the wear and tear of the machines.

To obtain data, two inductive sensors detect metallic objects and calculate the distance between them based on the speed and frequency of detection. The first one is placed so that it can detect the movement of the conveyor belt itself. The second one is placed in the rotor. Thanks to these two independent measurements it is possible to detect if both elements are synchronized or if there is a speed difference between them, which could indicate a malfunction of the belt or an excessive weight supported (similar measures, but below the usual average).

The selected connectivity equipment should have enough capacity for three independent digital inputs and processing ability to capture the data, store it and analyze it thanks to an algorithm that allows to detect anomalies directly, allowing to send an alarm if something breaks before even sending the data to the IoT platform (Cervello). Due to these requirements the solution is designed with an MTX-IoT-S, an IoT modem with up to 8 digital inputs/outputs. The MTX-IoT-S, in addition, sends the data already processed in pre-recorded timestamps to an IoT platform (Cervello), which adds another complex layer of processing that allows analyzing the patterns in the behavior of the conveyor belts to foresee their deterioration.

The solution also includes a temperature sensor located next to the conveyor belt motor to monitor the operating temperature and detect overheating or abnormal temperatures. This information is also processed to send an alarm if the temperature is outside the range, and it’s also stored and analyzed in the IoT platform (Cervello).

For more information, please refer to the datasheet of the product:

Please follow your questions and inquiries to:

automatyka@maritex.com.pl

tel. +48 58 781 33 66

en

en