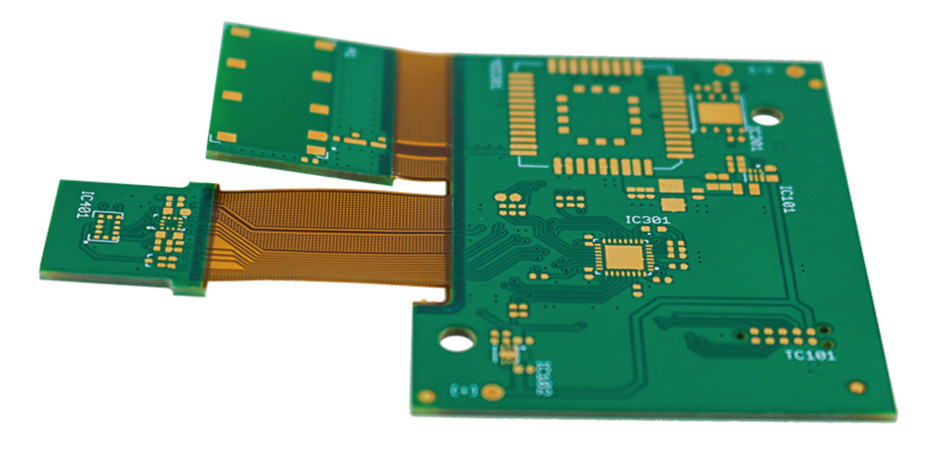

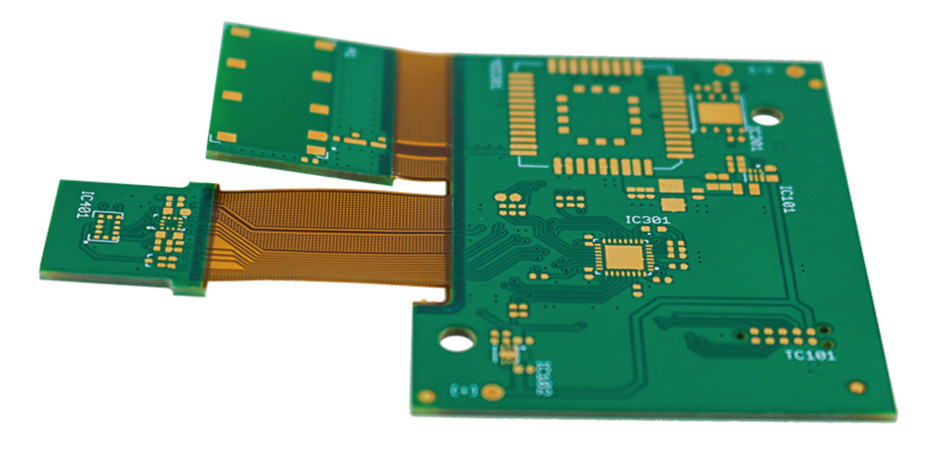

Rigid-Flex Printed Circuit Boards

We are expanding our offer of printed circuit boards in Rigid-Flex technology.

Innovation is driving the demand of smaller, smarter and more versatile devices. Rigid-Flex PCB is a technology that combines the best of two worlds – the stability of rigid boards and the flexible circuits. Rigid-flex technology offers a compelling array of advantages, while also posing a set of intriguing challenges.

The most significant difference between Rigid-Flex PCBs and traditional PCB is the integration of both rigid and flexible regions within a single board. Traditional PCBs consist solely of rigid materials and are not designed to bend or flex. In contrast, Rigid-Flex boards are designed to accommodate bending and flexing in specific areas.

Standard printed circuit board designs have several advantages:

- Cost-efficiency: traditional PCBs are generally cost-effective to manufacture, making them a preferred choice of many standard electronic applications;

- High-volume production: when electronic products are produced in high volumes, traditional PCBs can be mass-produced efficiently and cost-effectively;

- Standard form factors: for applications where standard rectangular or square PCBs fit well within the enclosure, traditional boards are sufficient.

Flexible circuits have several advantages:

- Bendability: flexible PCBs are usaful where continuous bending or flexing is needed in applications. They can conform to various shapes and fit into tight spaces;

- Lightweight: flexible PCBs are lightweight, what is advantageous in weight-sensitive applications such as drones and portable electronics;

- Reduced space requirements: in applications where compactness is essential, flexible boards offer space-saving advantages.

By combining both of the above types of PCBs into the Rigid-Flex technology we obtain a solution that will enable the development of further technology of electronic products on the Polish and global markets and we will receive the following advantages in one product:

- Space efficiency: Rigid-Flex PCBs are highly space-efficient, as they eliminate the need for connectors and reduce the need for additional interconnects. They can be folded or bent to fit within tight spaces, making them ideal for compact and densely packed electronic devices;

- Reliability: fewer connectors mean fewer potential points of failure, improving overall system reliability. Rigid-Flex boards are less prone to connector-related issues;

- Durability: Rigid-Flex boards are designed to withstand mechanical stress, vibrations and temperature variations, making them suitable for applications in harsh environment;

- Reduced assembly costs: despite the initial complexity of manufacturing, Rigid-Flex boards often result in reduced assembly costs due to fewer components and manual assembly steps;

- Complex geometries: Rigid-Flex technology enables the creation of complex board shapes and three-dimensional configurations that are challenging to achieve with traditional PCBs.

For more details, please don’t hesitate to contact us: pcb@maritex.com.pl

en

en