Ultrasonic welding system

Maritex would like to inform you about adding to our offer ultrasonic welding systems .

Ultrasonic welding is an industrial technique whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. It is commonly used for plastics, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together.

Ultrasonic welding equipment consists of ultrasonic welding transducer, ultrasonic welding generator, ultrasonic horn, machine press, and component supports booster.

Main Functions of Ultrasonic Generator

- Automatic Frequency Tracking: ultrasonic transducers generate heat, which can lead to change in transducer frequency. Our generator tracks the transducer’s frequency and fine-tunes generated signal to meet transducer actual frequency.

- Digital Amplitude Setting: allows users to set accurate amplitudes according to application. This functionality provides a larger range and repeatability of settings than analog systems. The amplitude can be adjusted in a large range: 20% ~ 100% smoothly adjustable. This is the great advantage over traditional generators that are difficult to work with low amplitude.

- Intelligent Fan Control: Depending on internal temperature generator controls fan operation. If internal temperature is lower than 45°C fan stops after 30 second of idle work. Otherwise, cooling system is active until temperature drops. There is also a built-in over-temperature protection set at 80°C. This advanced system reduces amount of dust inhaled to the device and improve reliability of the device.

- LED display and indicators: Legible LED display shows the working current, frequency, time, and amplitude.

Ultrasonic transducer

Ultrasonic Welding Transducer are designed to operate at a specific frequency from 15 to 300 kHz for different systems and applications. Most metal welding systems operate at 20 to 70 kHz, with 20 kHz being the most common frequency.

- High Performance: high mechanical Q value, the conversion efficiency of electroacoustic up to more than 90%.

- Large Amplitude: high seismic velocity of the oscillator, with an amplitude increase of more than 50% compared with that of the magnetostrictive transducer.

- Heat Resistance: high quality material, good heat resistance, low resonant impedance, low calorific value.

- Strong Structure: high quality standard steel bolts, high reliability.

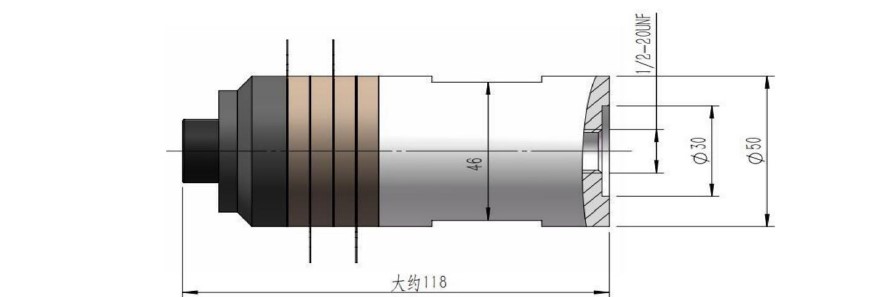

Ultrasonic Transducer 20KHz 2000W – Size Drawing

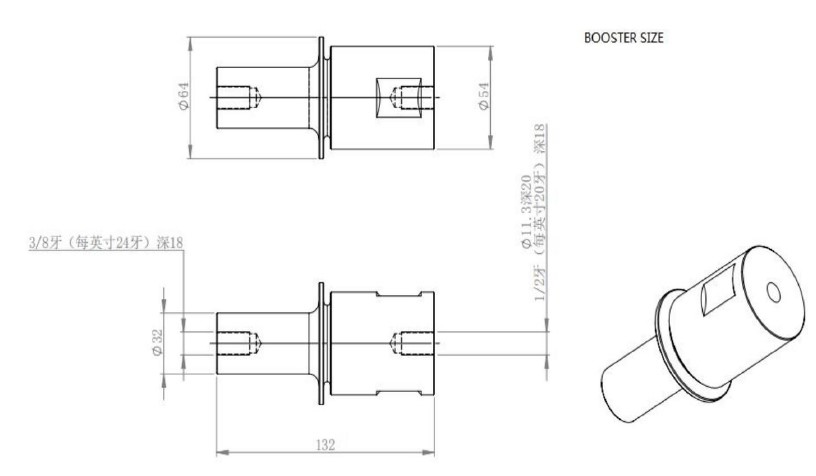

Boosters

Boosters are designed to change the value of the vibration amplitude (increase / decrease).

We offer a wide range of boosters with different gain and made of various materials. We select boosters individually for each application.

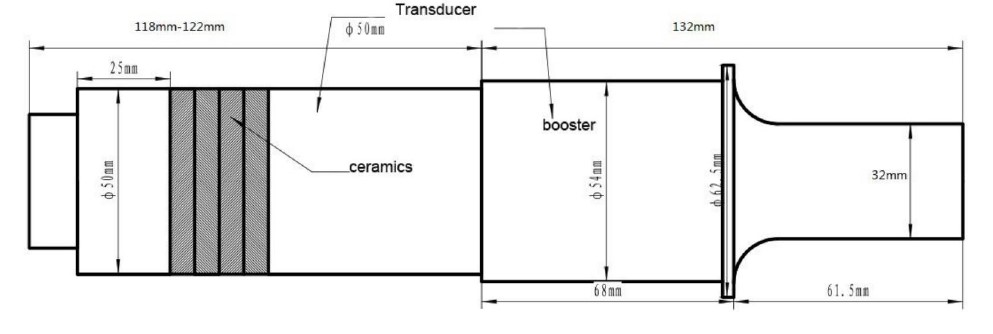

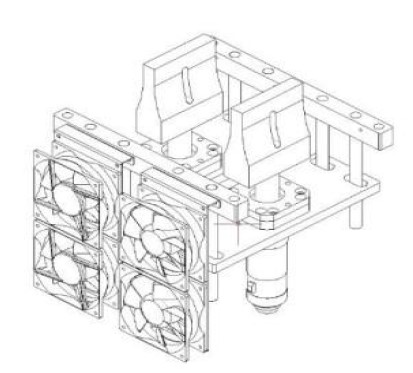

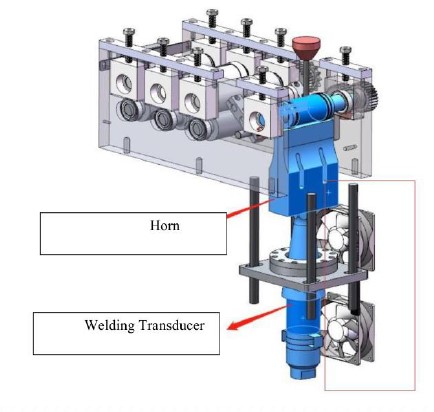

Ultrasonic Transducer with Booster

Horn is an actuator of the booster, which transmits vibrations to the welded material. The size and shape of this element are properly adjusted to the customer’s requirements.

Horns are made of various metal alloys depending on the frequency with which they must work and the material to be welded.

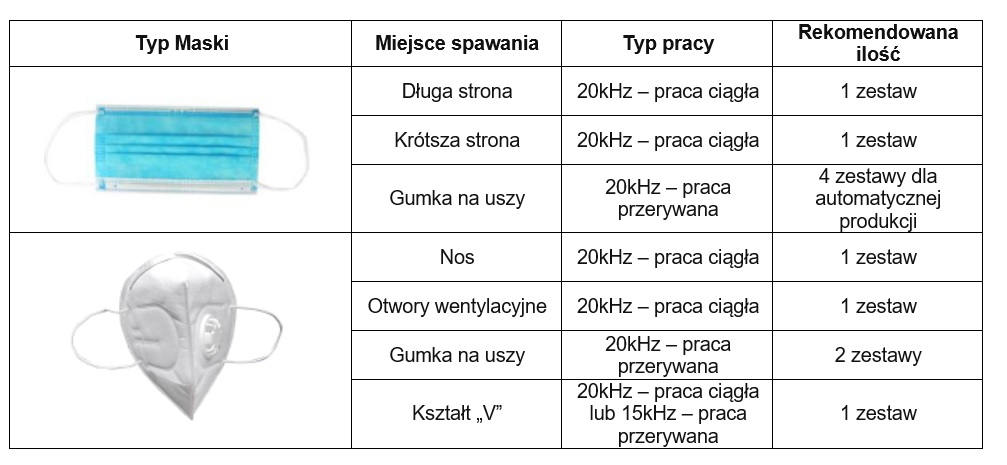

Examples of 20khz Ultrasonic Welding Solutions

Install showing:

In case of technical questions feel free to contact us by phone: +48 58 662 05 79 or email: sensor@maritex.com.pl

en

en